How Digital Twins Are Transforming the Manufacturing Industry

Digital twins represent a significant technological advancement in the manufacturing sector. By creating virtual replicas of physical assets, they allow for real-time monitoring and analysis. This capability leads to improved operational efficiency and resource optimization. However, the implications of digital twins extend beyond immediate gains. As manufacturers adopt this technology, they may uncover deeper insights into their processes and uncover new avenues for innovation. What lies ahead in the evolution of this transformative tool?

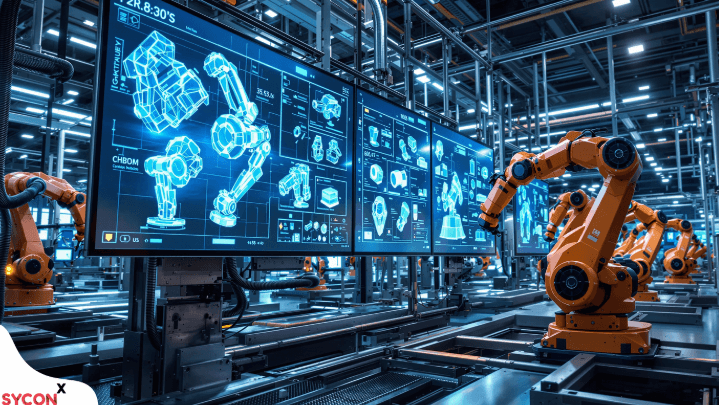

The Concept of Digital Twins in Manufacturing

As industries increasingly adopt advanced technologies, the concept of digital twins in manufacturing has emerged as a transformative approach to optimize production processes.

These virtual replicas of physical assets facilitate real-time monitoring, enabling manufacturers to analyze performance, predict failures, and enhance efficiency.

Benefits of Implementing Digital Twins

Implementing digital twins in manufacturing offers a multitude of benefits that significantly enhance operational efficiency and decision-making processes.

These virtual replicas enable real-time data analysis, leading to substantial cost savings through optimized resource allocation.

Additionally, predictive maintenance minimizes downtime by forecasting equipment failures, allowing manufacturers to proactively address issues, thereby sustaining production flow and enhancing overall productivity in a competitive landscape.

Future Trends and Innovations in Digital Twin Technology

The evolution of digital twin technology is poised to redefine manufacturing landscapes, driven by advancements in artificial intelligence, machine learning, and the Internet of Things (IoT).

Future innovations will emphasize AI integration for enhanced predictive analytics, enabling real-time decision-making and operational efficiency.

This synergy will foster a new era of agility and customization, allowing manufacturers to adapt seamlessly to dynamic market demands.

Conclusion

In conclusion, digital twins represent a pivotal advancement in manufacturing, offering enhanced operational efficiency through real-time monitoring and predictive analytics. While some may argue that the initial implementation costs can be prohibitive, the long-term benefits—such as reduced downtime and optimized resource allocation—substantially outweigh these concerns. As the technology continues to evolve, manufacturers embracing digital twins are poised to gain a competitive edge, fostering innovation and sustainability in an increasingly demanding market landscape.